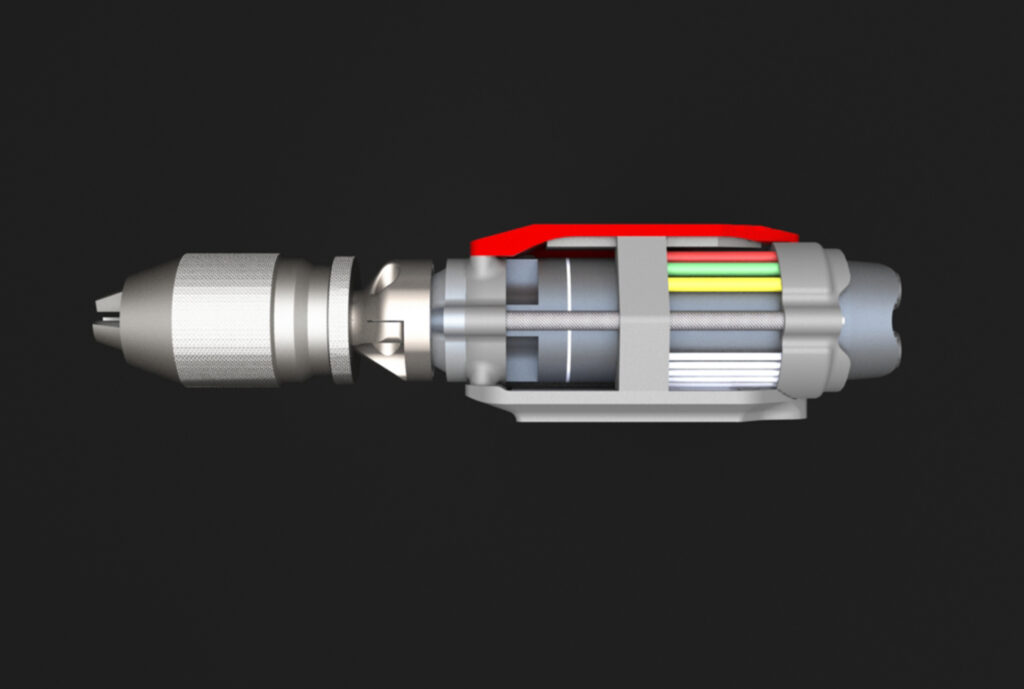

The modern cordless drill re-imagined. Inspired by equipment used in machine shops, race track, and gun range. The Gore Compact Precision drill uses a high rpm brushless sesnored motor connected to a cycloidal gearbox driving an interchangeable drive hub.

Specification

- 250w Brushless NEMA 23 Standard Motor

- 500 in Lbs / 40ft lbs / 55nm Torque Sensing Drive (Optional Torque Sensing Impact)

- Jacobs JT-2 Taper, 1/4in Hex/3/8 Square drive, 1/2-20 Swappable Drive Hub.

- Cyclodial Reduction Gearbox

- Open Source Battery

- Programmable Control System

Current tools have replaced the cast aluminum housings of the past with injection molded clamshell housings, and internal components have ended up one offs without any universal replaceability. This also leads to tool lifetimes ranging in the 5-8 years (in a non professional setting), and a tool which reflects that in construction and quality. I use these tools, and appreciate their performance, packaging and value, but there is only so much you can package into a product at these price points.

Working from NEMA standard motors and gearboxes, the Compact Precision Drill offers the user adjustable torque and rpm using electrical shunt, motor sensor, and integrated torque sensor feedback. These same sensors can be used to control or program modes such as drilling, tapping, or fastening with torque, and bottom limiting functions.

With such features, the user requires new aids to enable proper use. Auto sensing orientation mode gives either vibrating or visual feedback allowing the user to know if they are aligned perpendicular to the work surface, or fix an alternate alignment. Complementing this feature is the ability to open loop tune for drilling, tapping or fastening with either user force, or tool load variables. This allows the user to set a screw mode which can pause inputs on bit slip, and catch a drill or tap break before the user could pause their input.

Modes and Features

Drill

- Max RPM

- Chip Load Limiter w/Open Loop Force/Rpm Feedback

- Angle/Alignment and Force Alarms

- Free Load/Overload Stop

- Full Auto Throttle

- User Programmable Profile

Tap

- Max RPM

- Tool Head Torque Limiter w/Open Loop Force/Rpm Feedback

- Angle/Alignment and Force Alarms

- Bottoming Reverse

- Programmable Max Rotations

- Full Auto Throttle

- User Programmable Profile

Fasten

- Max RPM

- Tool Head Torque Limiter w/Open Loop Force/Rpm Feedback

- Angle/Alignment and Force Alarms

- Bottoming Reverse

- Programmable Max Rotations

- Full Auto Throttle

- User Programmable Profile

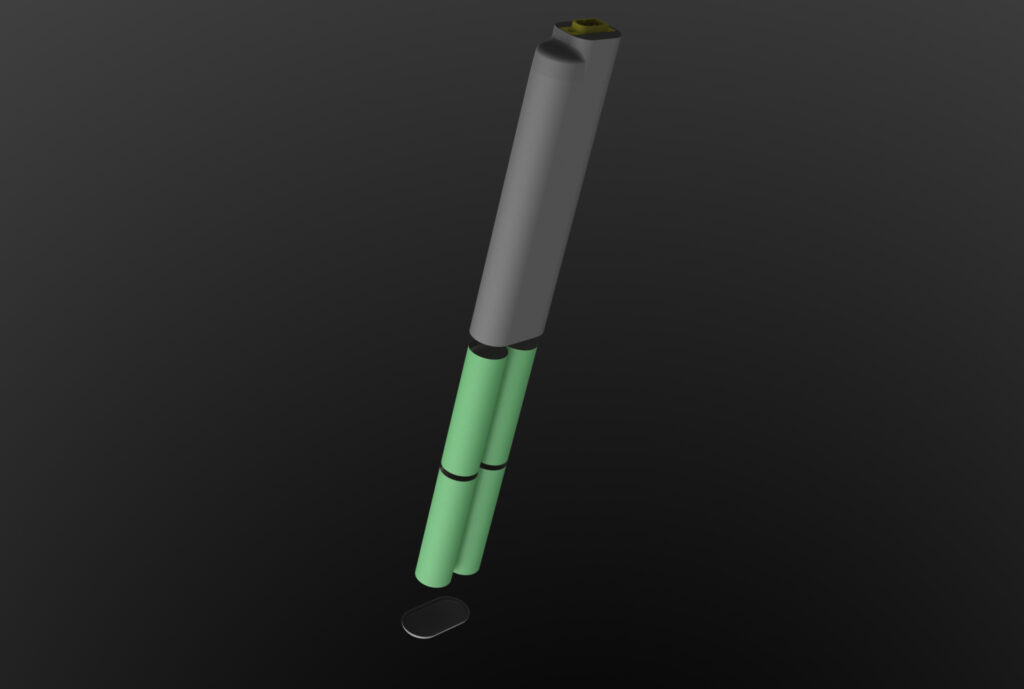

Powering these features is a 4 cell 18650 battery with integrated battery management system which is open source. This allows the battery investment to be as long as the cell size is available, and allows upgrading to new chemistries available in the same cells. Helping to future proof the tools investment.

Powering these features is a 4 cell 18650 battery with integrated battery management system which is open source. This allows the battery investment to be as long as the cell size is available, and allows upgrading to new chemistries available in the same cells. Helping to future proof the tools investment.

Paired with this host of technology is a simple software sweet with basic core functions and the ability to access said core functions on the tool with a limited of number of simple durable tactile inputs. Programming or adjusting features should be easy to setup for a particular use case and those profiles are easily accessible.

Use Case

Automotive

While assembling the engine bay of a car a service technician may access between 10-300 pieces of hardware with a variety of torque ranges and hardware types. Much of this hardware upon application can be accessed rapidly with an electrically assisted tool and extensions. Currently impact drivers of different power sources and types as well as hand hardware like ratchets and screwdrivers are used for both assembly and disassembly. Although the impact driver is great for disassembly and assembly larger hardware with known durable mating components, on more delicate components and softer metals it can lead to expensive broken bolts.

Working Example. The service technician is prepping a BMW X5 for service and must remove and install 10-15, 5-6mm pieces of hardware clamping plastic and steel parts. A simple application of the product requiring no programming or additional software sees the service technician dialing in the torque specification provided by the manual while in torque limiting mode, adjusts the max rpm to whatever they prefer, and the hardware is removed or installed with an ability to override automatic torque limiting functions in the event of stuck hardware. In a production environment the technician may program this job as a known job with process confirmation and process advancement capabilities alerting the user of required next hardware, and even a chuck change. This process could involve a log including tool orientation, force application or confirmations between processes to sign off on other work such as loctite application or the inclusion of replacement hardware.

Woodworking and Carpentry

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur

Fastening and Assembly

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur