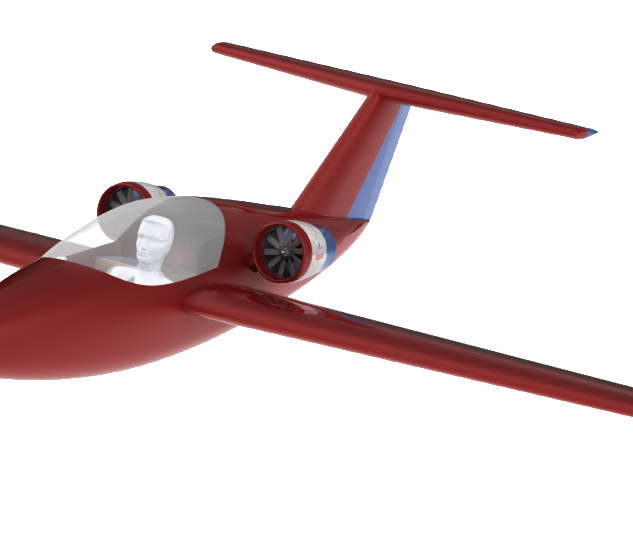

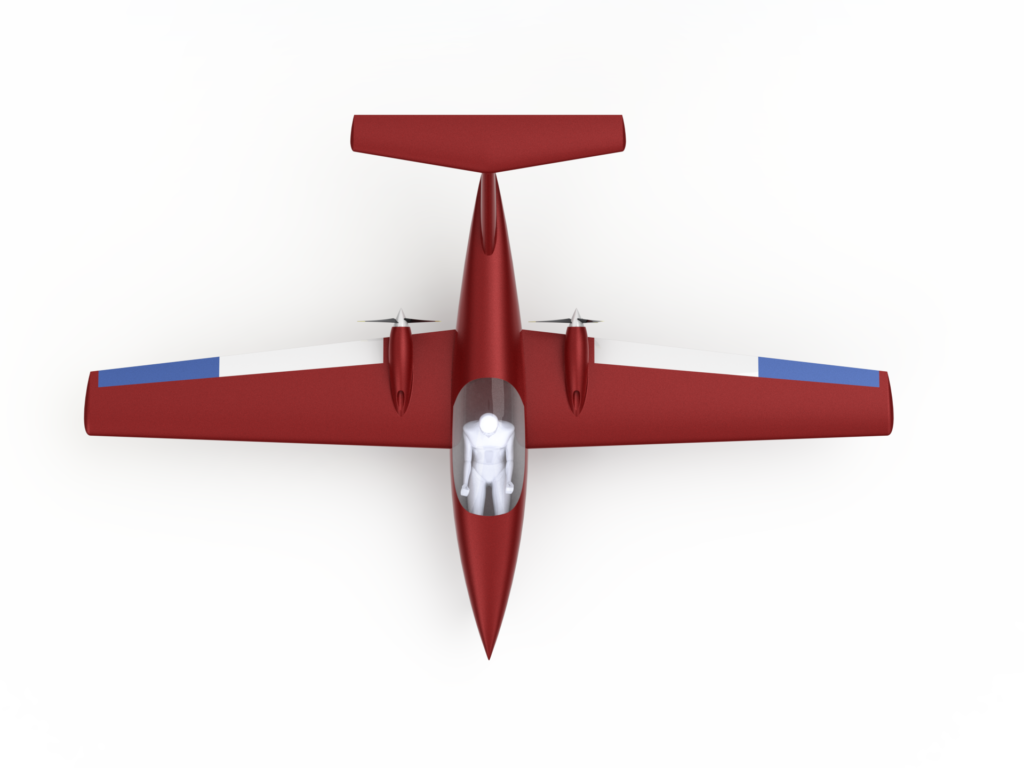

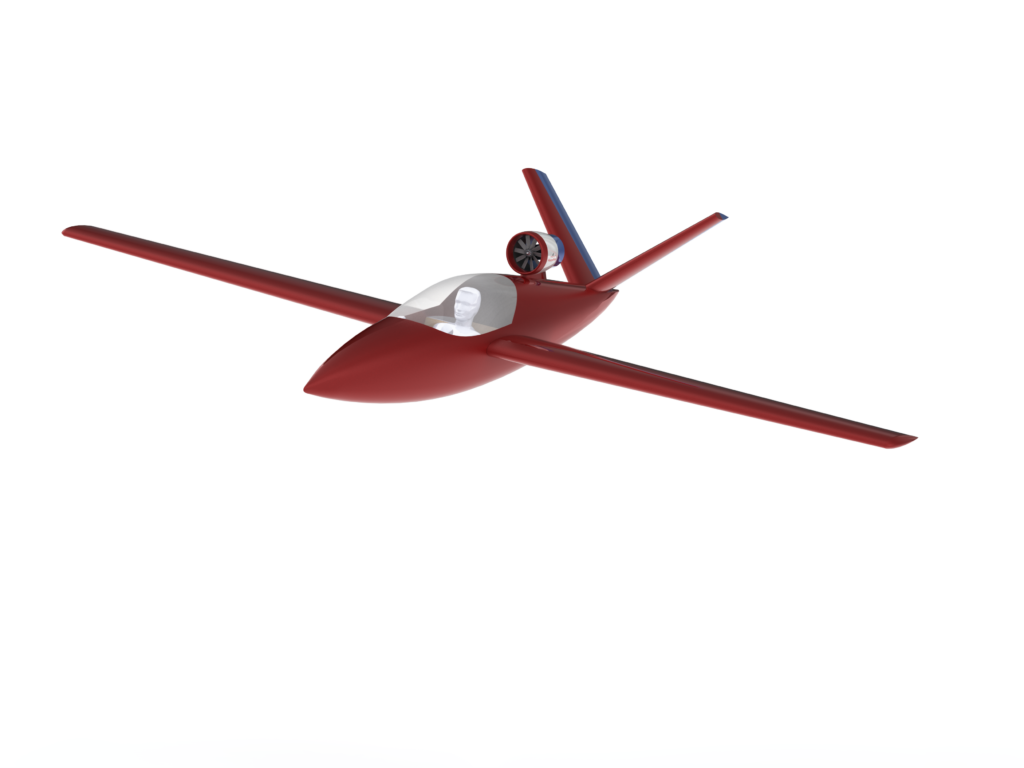

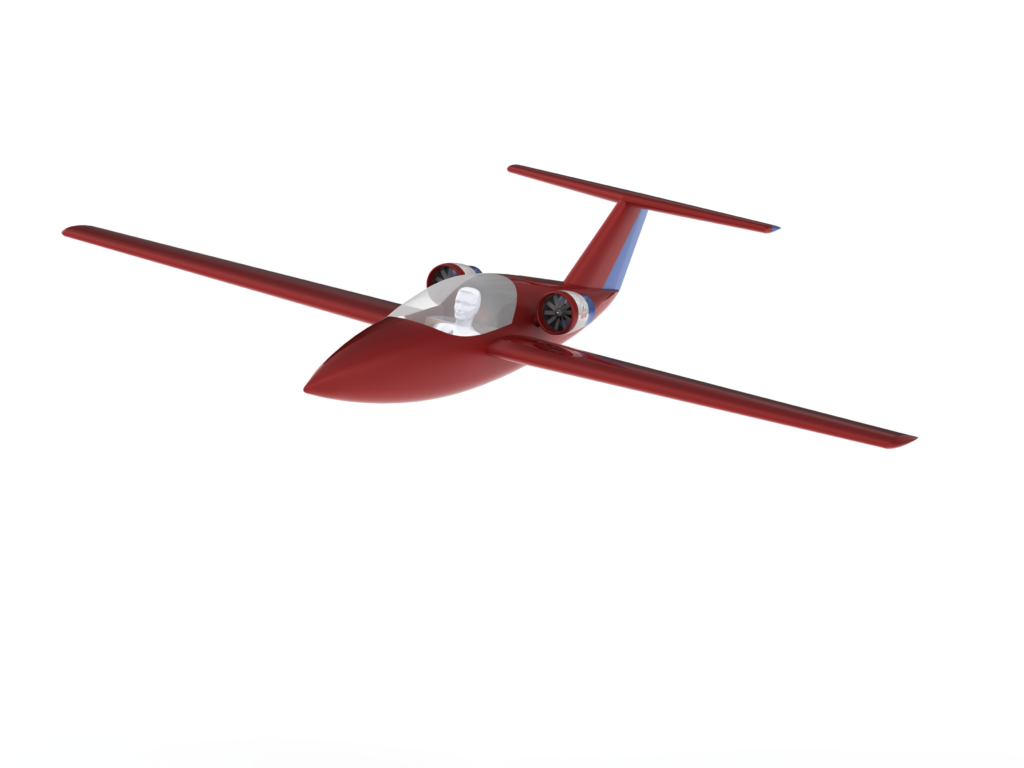

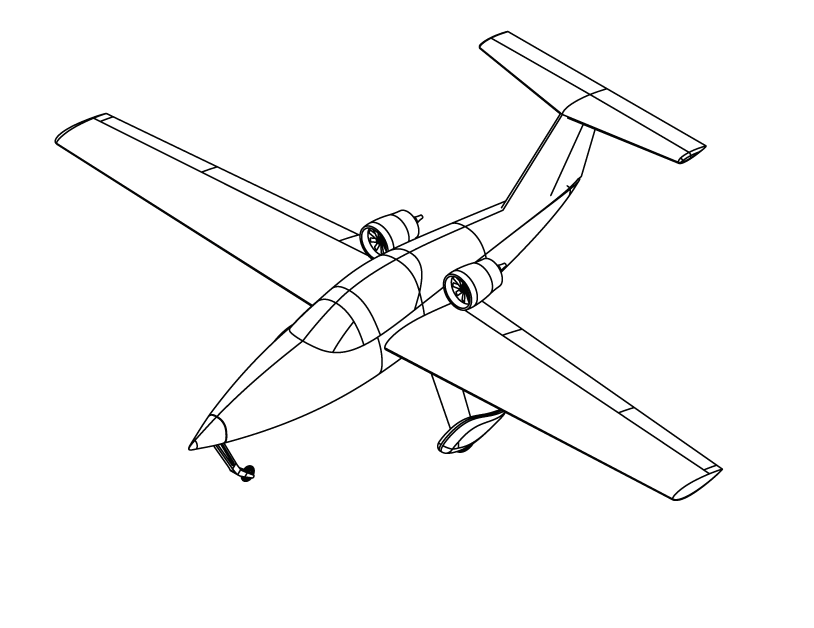

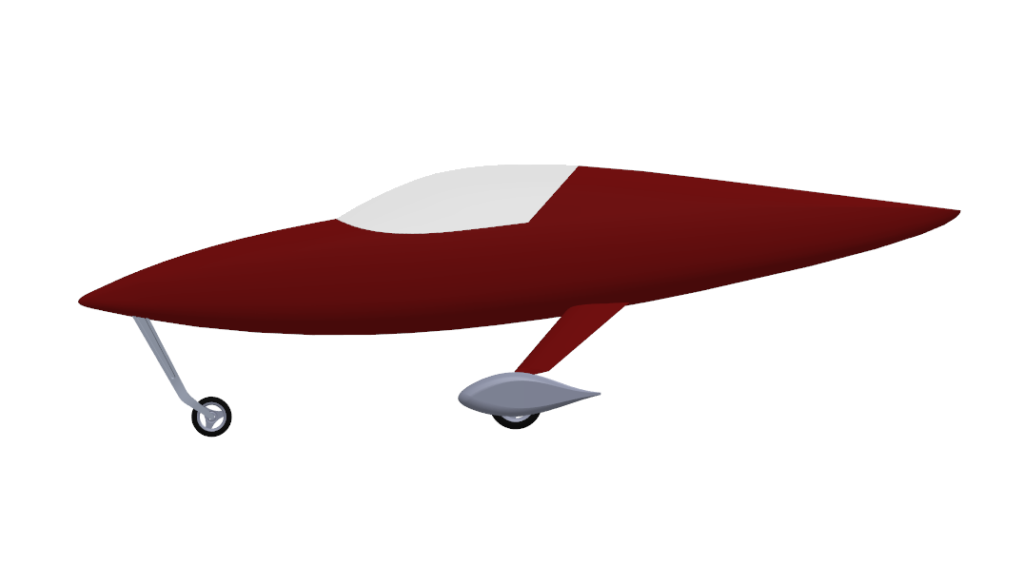

The Odyssey is a lightweight composites electric aircraft from the brain of Russ Emanis. The Odyssey is intended to highlight lightweight composites and home built aircraft by being a technological showcase built through the Advanced Composite Infusions program with EAA Airventure Oshkosh.

Background: Russell Emanis is composites process consultant who started with surfboards in his youth, all the way to overseeing composites Processing at Lockheed Martin on the F22 Program. Currently his work is focused on Aircraft manufacturers and offering independent consultation overseeing all facts of new product development and processing as well as managing the Advanced Composite Infusions program with EAA Airventure Oshkosh.

In November of 2018 Russ met Joshua Gore while consulting on an unrelated composites project, and started discussing what it might take to bring the Odyssey from his paper sketches and NACA profiles into reality.

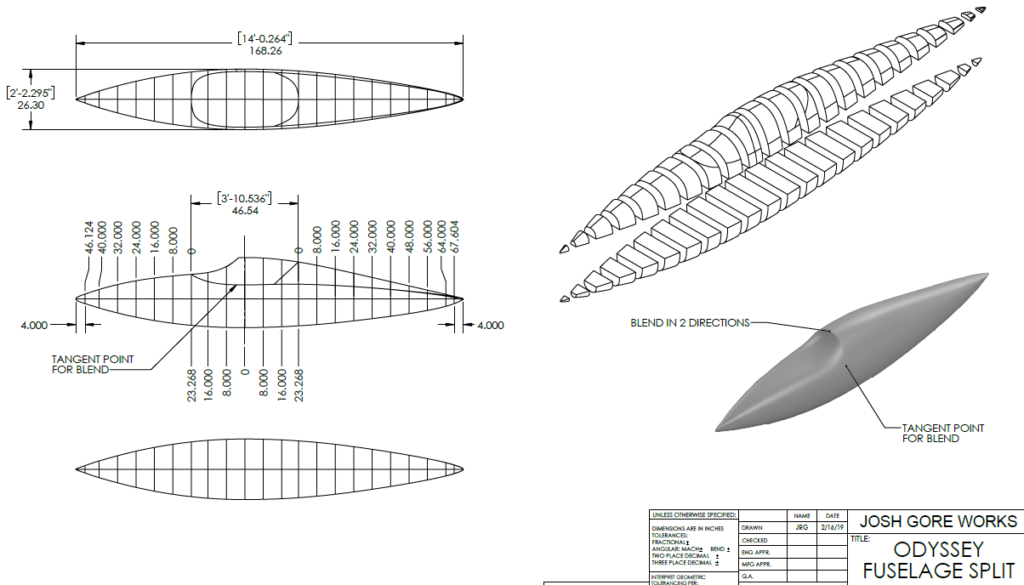

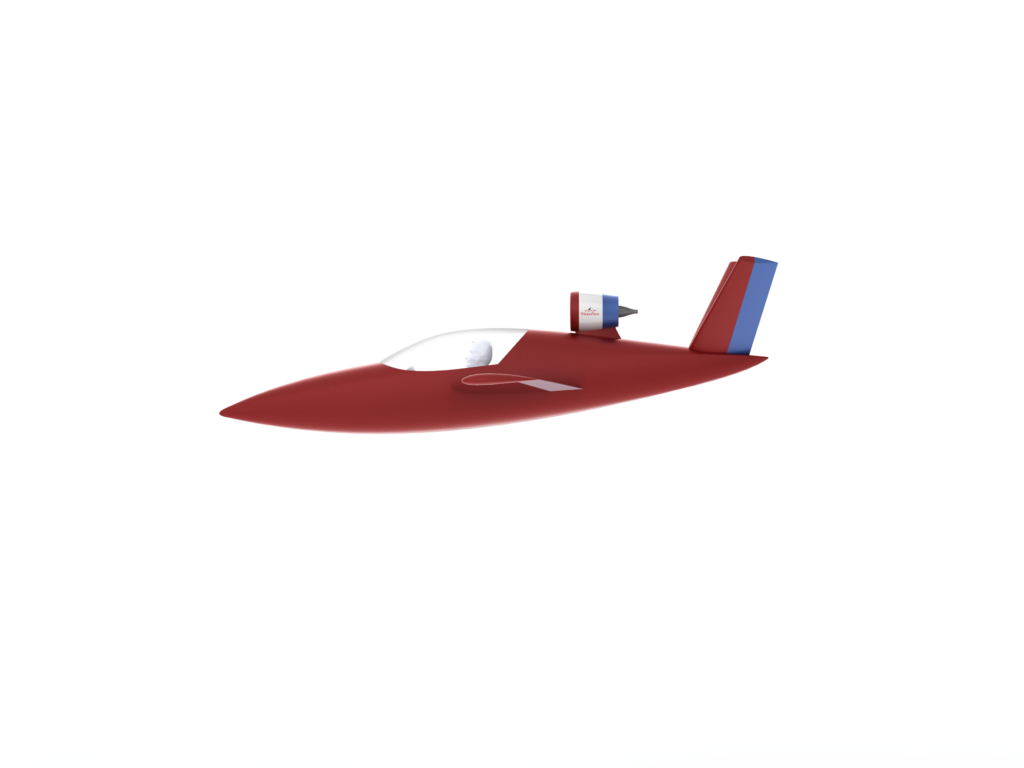

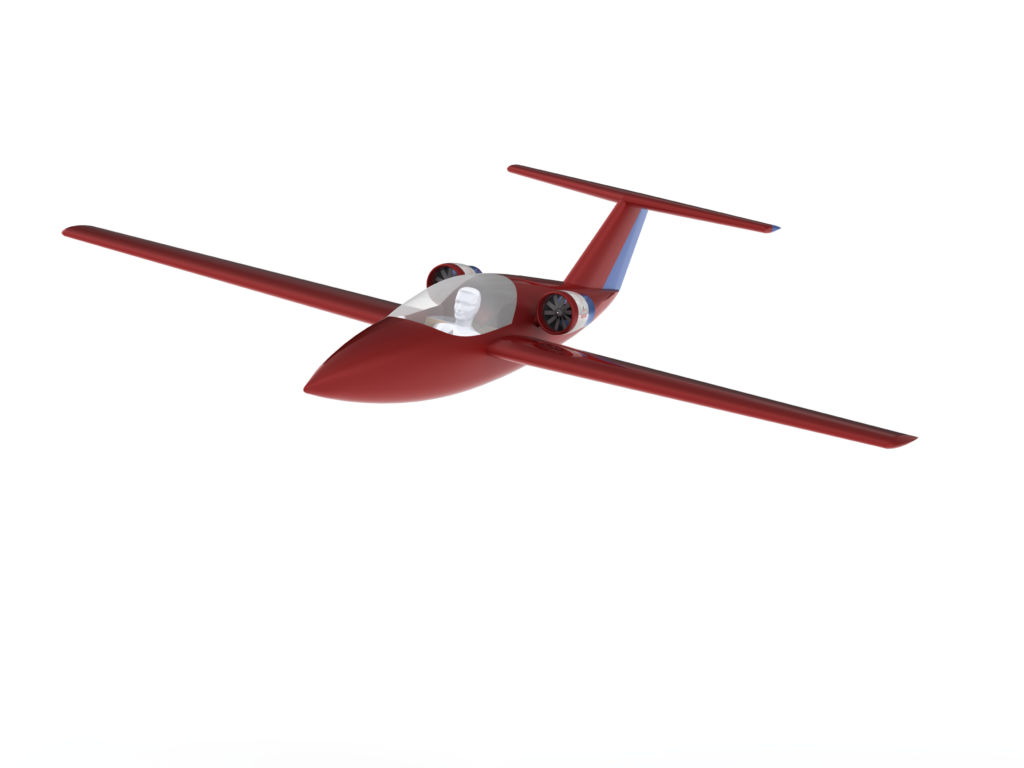

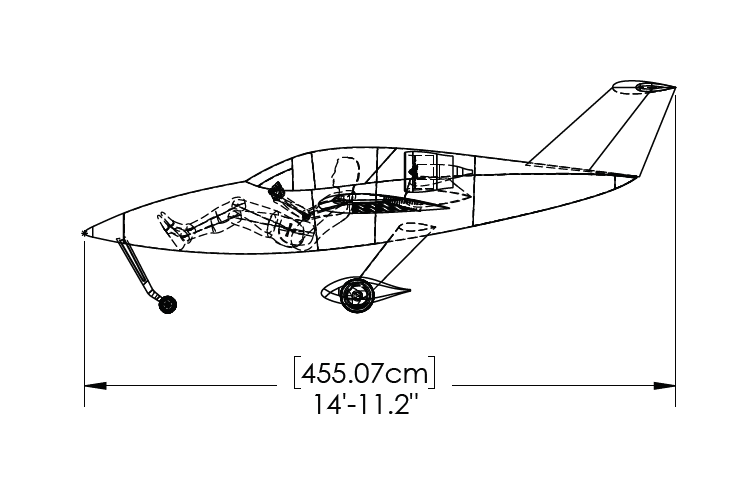

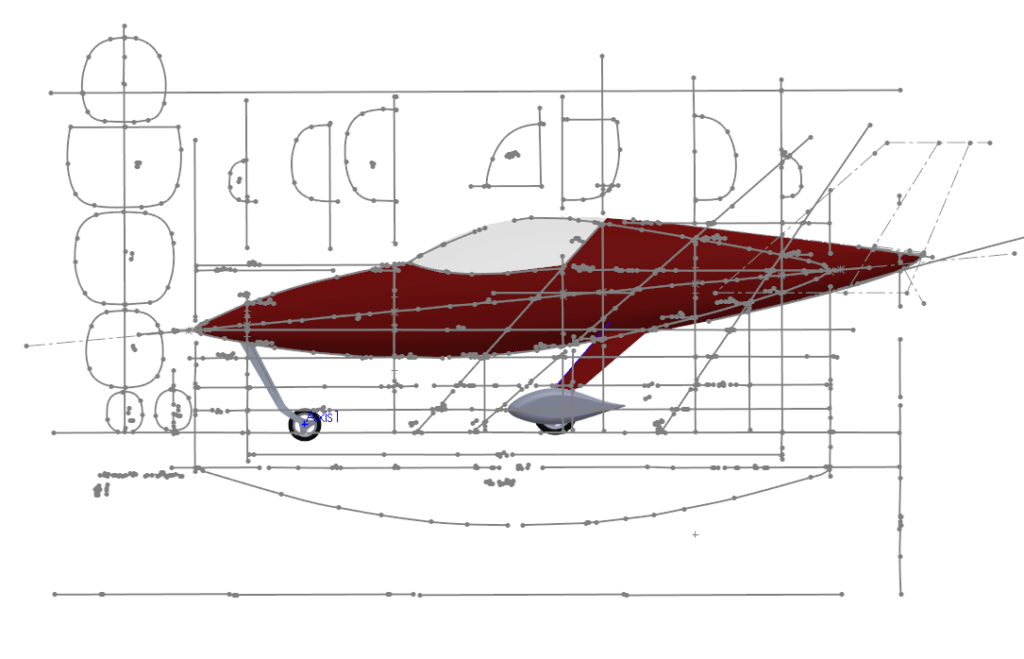

The project started without the knowledge of how the patterns and tools would be cut or produced, but with a truncated schedule we covered our bases. Two dimensional hand sketches were provided by Russ and the fuselage started to take shape. Changes were required immediately to the length and proportions, but it was done without requiring extra cross sections as the tail was stretched after the fuselage.

Provided

Lengthened

Final

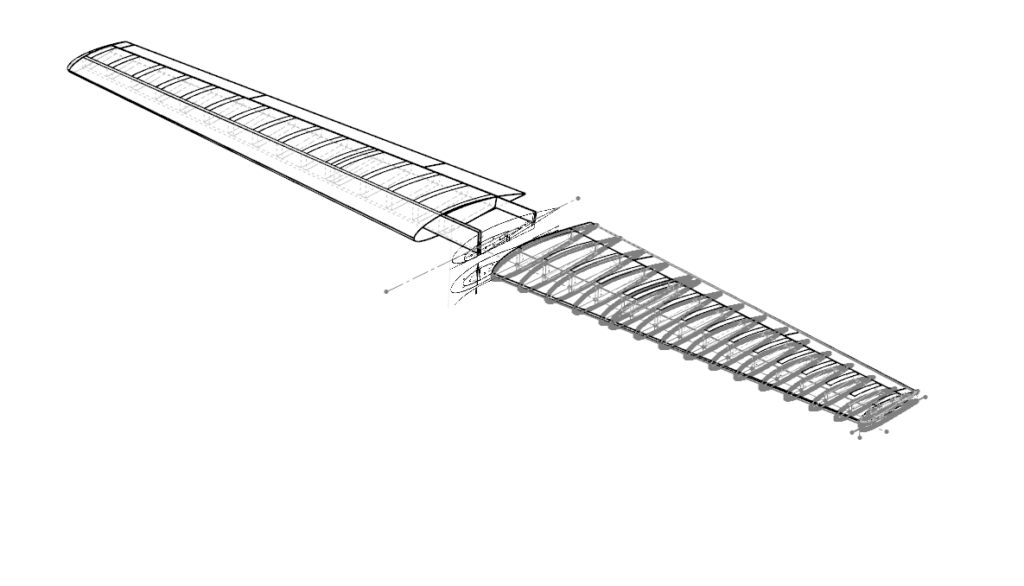

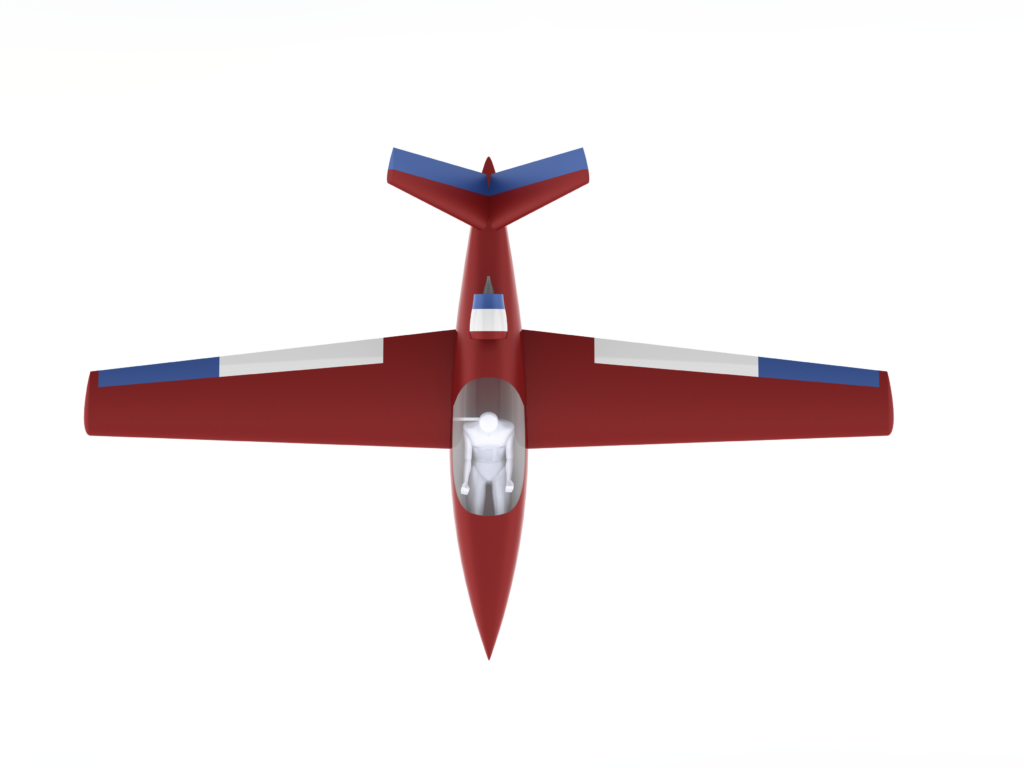

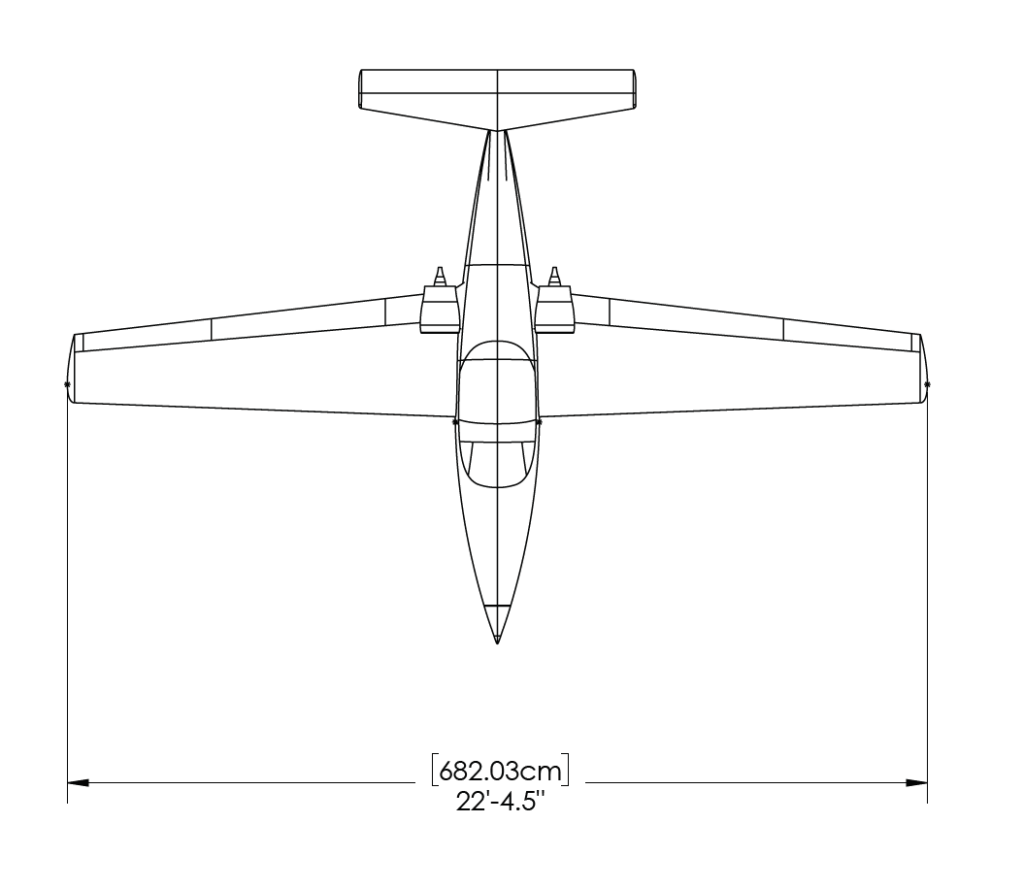

The fuselage, its surface area, and angular orientation with the horizon were provided to Russ and his team and NACA profiles for the wing were given in return. These naca profiles came with spar locations and a wing slowly took shape. This process was repeated with wing surface areas and location provided to Russ and his team and NACA profiles and location returned for the T-Tail and V-Tail configurations.

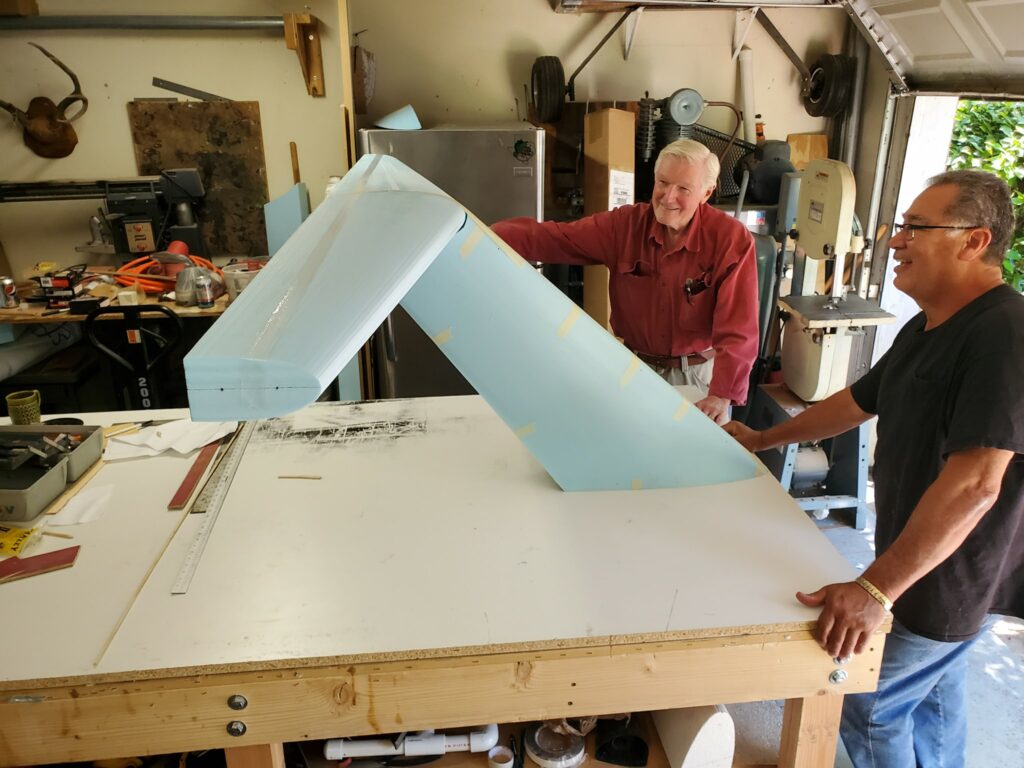

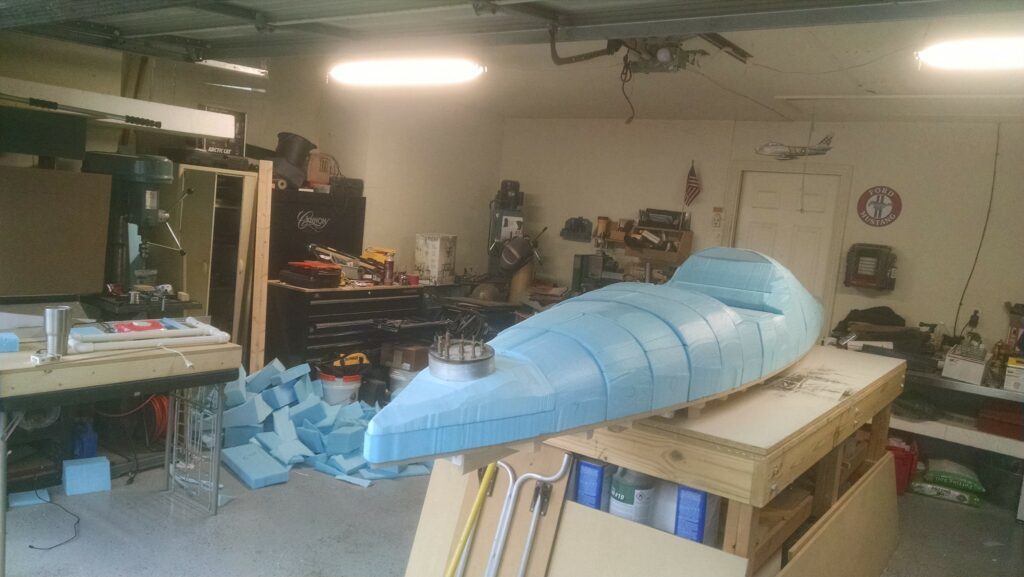

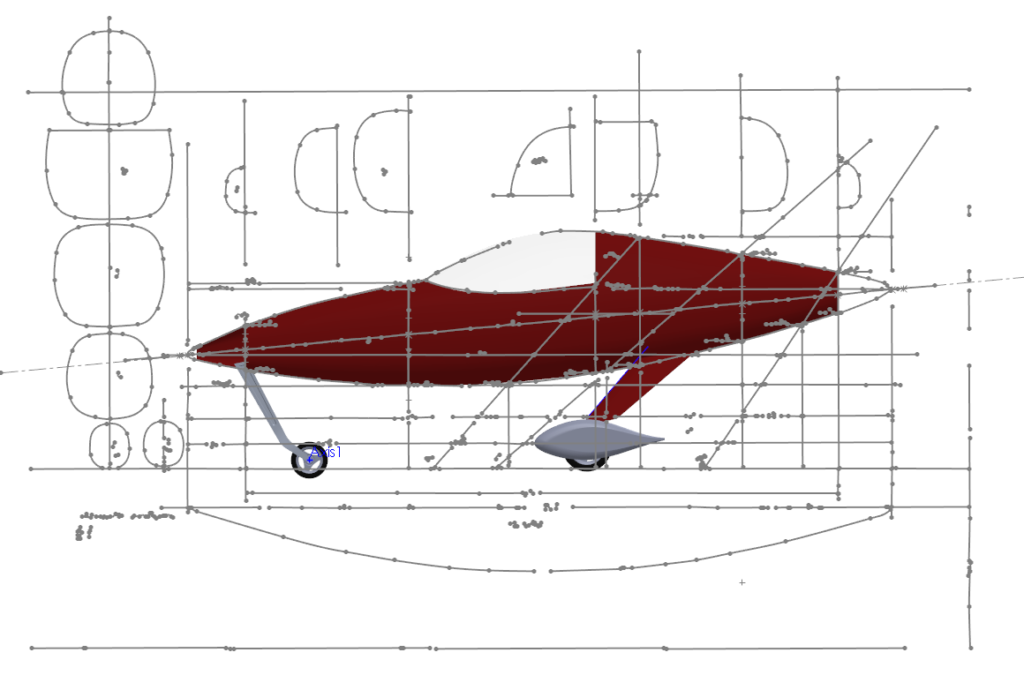

After the skins and spars were complete in both the wings and tail we started creating station drawings which involved splitting up the wings and fuselage and producing scale 1:1 drawings for reference or pattern creation. At this point Russ started cutting foam and documenting that process on his Facebook page. Russ used a combination of hot wire cutting, and hand finishing to create beautiful patterns which will end up creating great tools.

Russ has continued the progress with plans of pulling the first tools and parts at EAA Oshkosh 2019. To participate or view that process checkout the EAA Airventure Oshkosh Schedule with full day classes starting at 9am every day view more information here https://www.eaa.org/airventure/eaa-airventure-schedule-of-events and search for ‘Emanis’, or ‘An Odyssey of Composites’ Parts 1-5 .

Below are pictures of the tooling patterns ready to pull tools. As powertrains arrive and battery systems are tested final drawings can be produced for the Odyssey, but until then tune in!

Specifications:

Propulsion System(s) and Power Ratings

- System A: Vasyfan VF-250 Single Electric Ducted Fan (V-Tail)

- System B: Vasyfan VF-250 Dual Electric Ducted Fans (T-Tail)

- System C: 10-15kw Dual Electric motors driving Propeller(s) (T Tail)

Battery and Motor Controllers

- System A: 120v 300 Amp Dual Redundant BLDC Controller

Battery- 3kw-5kw Lithium Batteries - System B: 120V 300 Amp Dual Redundant BLDC Controller

Battery- 3kw-5kw Lithium Batteries - System C: 400V 200 Amp Dual Redundant BLDC Controller

Battery- 3kw-5kw Lithium Batteries

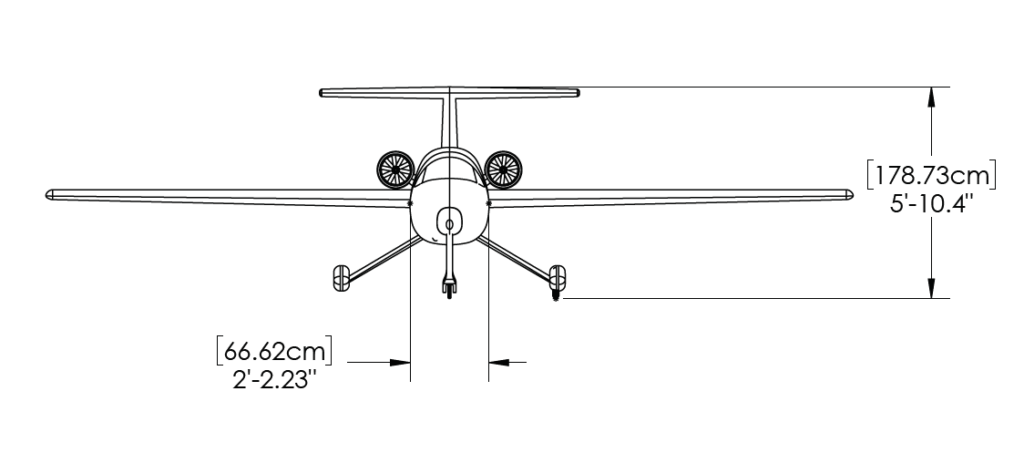

Size

Ratings and Specifications

- Cruise Knots TBD

- Max Knots TBD

- Stall Knots TBD

- Service Ceiling TBD

Weights and Capacities

- Gross Weight TBD

- Empty Weight TBD