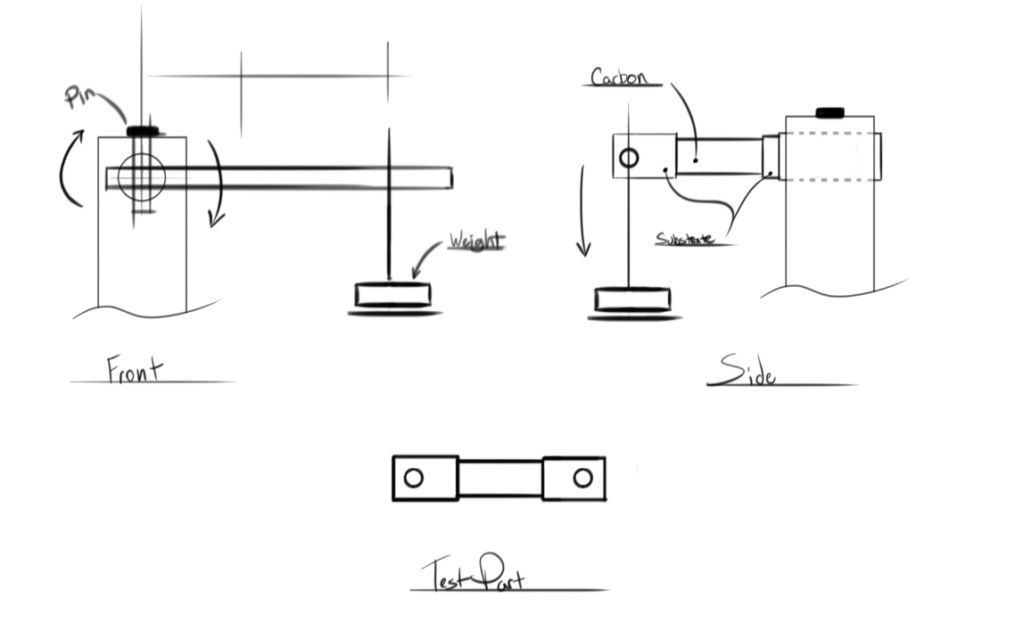

It’s time to build a fixture to test carbon tubing. For this project I am testing a 41mm tube with both bending and torsional loads as well as a combination of both. The purpose of this test is to compare tube layup options as well as bonding and substrates. The fixture will use a 2in bore and perpendicular pin located within a 3.5in box section of mild steel. This fixture could be used later to simulate a rigid head tube if adapters were constructed.

While the fixture is being fabricated the first sacrificial carbon was readied. This test includes a torsionally oriented carbon layup, and aluminum bonded by 3M epoxy with simple abrasion/mek preparation to all bonding surfaces. To test Torsional loads the substrate has a hole intended to align with the pin on the fixture side and torsion arm on the load side.

- 3M Epoxy and Bond Line Beads

- Non Sagging

- We Wait.

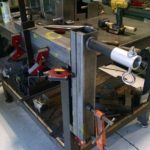

The fixture is fabricated from a combination of mild steel, 4130 and bolted to larger, weighted semi permanent structure. Then it’s simply a matter of loading and measuring and recording our findings, rinse and repeat.

- Cutting the stock

- Fit and Finish

- Finally Square

- Ready to Weld

- Welded on location.

- Pin Hole

After spending time with the propane torch getting some heat into the parts I set the tig to max at 150 and and started stitching the assembly together. After stitching I inspected that the assembly was square and finished welding by working my way from outside in.

The finished part with a small test load. This rig will be fitted with some measuring equipment and tests will commence.

Lavallard

Bonjour combien coûterait la fourche. Vendez vous votre prototype